Screw Jacks are mechanical devices used to convert rotary motion into linear movement and are widely employed across a variety of applications.

Screw jacks come in several varieties, from worm gear, bevel gear and ball screw types. All are designed to lift, position, align, push or pull loads ranging from several kilograms up to several tonnes.

What is a screw jack?

Screw jack is mechanical devices used to lift moderately heavy loads. In addition, they may be employed for raising and lowering aircraft horizontal stabilizers as well as providing adjustable supports for heavy loads such as house foundations.

A jack consists of a vertical screw with an attached top-mounted load table attached at its base that screws into a threaded hole in a stationary support frame with wide base on the ground. A rotating collar on its head features holes for attachment of metal rod handles to complete this setup.

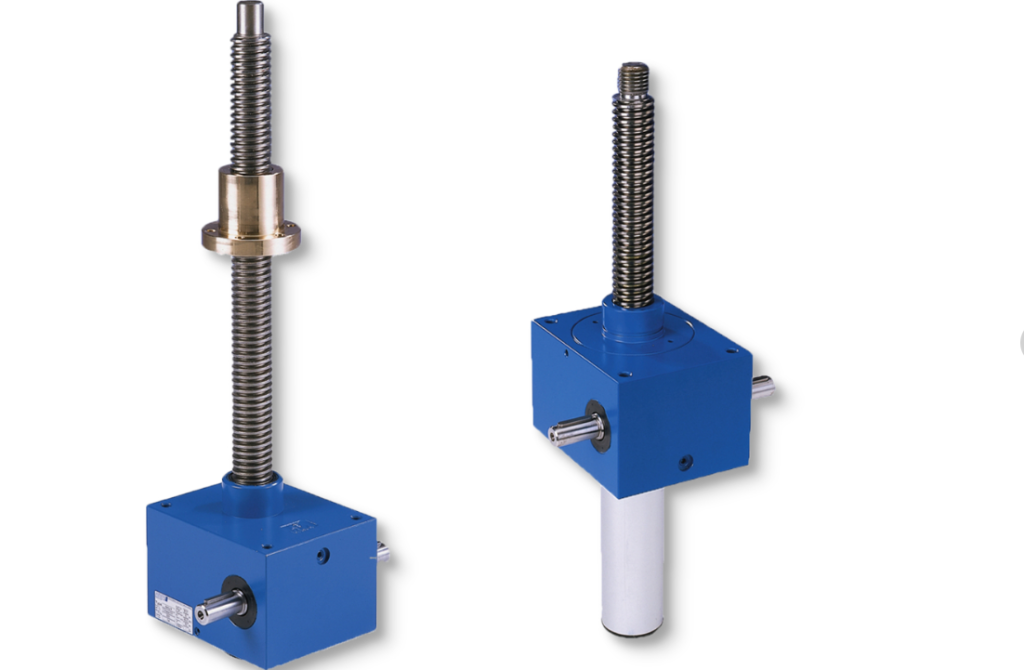

Machine and ball screw jacks offer different design characteristics to meet various motion application requirements, providing more options than ever for motion solutions.

How does a screw jack work?

Screw jacks are one of the most widely-used mechanical actuators for lifting, positioning and aligning loads in industrial settings. They’re often found in industries as diverse as Steel Works Equipment to Water Processing to Pharmaceutical, Medical & Laboratory Equipment to Packaging Equipment to Nuclear & Aerospace as well as General Mechanical Handling applications – just to name a few!

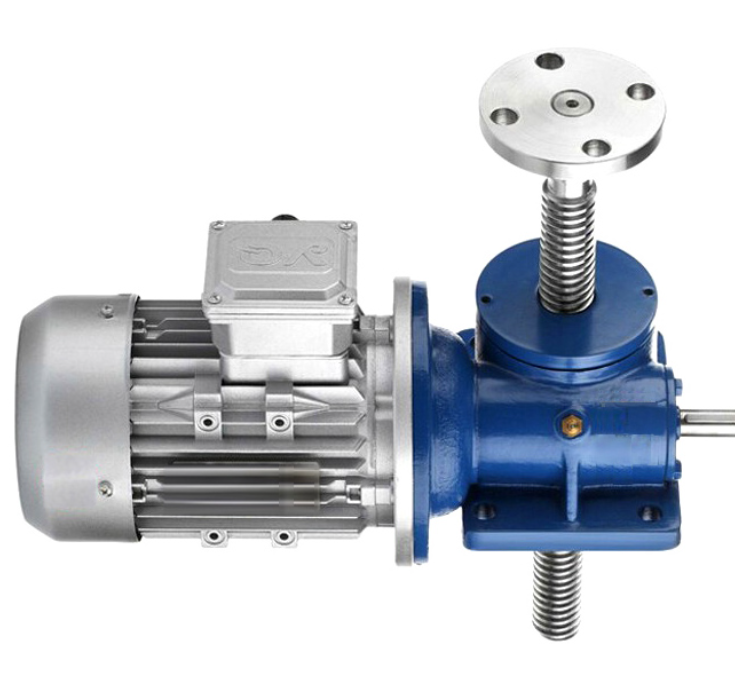

A jack is composed of a heavy vertical screw mounted at its top with an attached base that rests on the ground, activated via handwheel or motor control and designed to raise and lower loads as necessary.

Machine screw jacks use worm drive systems to convert rotation into linear motion, providing reduced energy consumption, higher reliability and more predictable lifecycle than ball screws.

Ball screws are suitable for applications where constant force is necessary, such as raising and lowering maintenance platforms, opening/closing air dampers, oven doors, sluice gates or adjusting tooling machine beds. However, ball screws tend to perform more efficiently if friction is an issue.

What is the purpose of a screw jack?

Screw jacks are mechanical actuators which use hydraulic pressure to move loads up or down and support them securely, making them versatile tools for applications ranging from building construction to satellite positioning.

Screw jacks work by converting rotational motion into linear movement using threaded screws and worm wheels, thus producing greater force than could be generated using standard load jacks alone.

A screw jack can be powered either by an electric motor or hydraulic system; either option provides energy-saving benefits since only power is used during lifting of the load and then held stable without additional electricity or hydraulic oil needed to keep its position secure.

What are the types of screw jacks?

There are three primary designs of screw jacks available, namely machine screw jacks, ball screw jacks and bevel gear jacks.

Consider your load conditions and duty cycle when selecting a jack. If the system operates frequently, a ball screw jack may provide better energy use with its high duty cycles and reduced energy use.

Thread type should also be taken into account when choosing a lead screw threading configuration. Trapezoidal screw threads, for instance, are popular among engineers due to their easy machining and large load-bearing capacity.

However, this type of screw thread tends to experience higher friction levels than others and this may reduce efficiency and make machine screw jacks less suitable for certain applications.

Keyed translating screw jacks prevent rotation by employing a key attached to their housing and milled into their lifting screw, stopping it from turning. While this option is available with acme screw jacks, ball screw jacks do not feature this design feature.